The following is an interview with Jamin Haddox of Cafe Imports. This flows from conversations in early November 07. It's good that the questions asked then are still so pertinent. Jamin's boss has a scathing article on storage/transport bagging methods for green coffees in the recent issue of Roast Magazine that is worth a read. His opinion's on freezing are worth noting as they break with notable wavers on the subject. We will follow up this green storage focus with a post of our own trip to Guatemala and the success barismo has had in this area with the invaluable Mr. Martinez which addresses the last answer Jamin provided in this interview.

barismo: What is your role with Cafe imports and how long have you been with the company?Jamin: I'm the Quality Control Manager for Café Imports. I'm in charge of the cupping lab, and am responsible for roasting, cupping, grading, and all other quality-related issues. I've been with Café Imports since September of 2006.

barismo: We talk a lot about preservation of coffee but it's a very complex topic.What factors affect fading/aging/decay and what factors are qualified as contamination?Jamin: It is very complex. At Café Imports, we've designed some basic experiments to help us learn and understand in more detail what these factors are. Let me point out that I'm not a scientist, but am learning, slowly, what some of these factors may be. A lot of things can cause coffee to age, including its own respiratory processes as it sits after processing. Free moisture and water activity play a key factor in coffee flavor deterioration. Water activity is a way to describe water's specific energy, which can be explained in simpler terms as how stable the free moisture is inside the coffee. Put another way, water activity can describe how willing water is to enter or leave the bean. Water bonds readily to volatile chemicals in coffee, many of which are responsible for coffee's unique flavors and positive cup attributes. So water in coffee can act like a transport mechanism, carrying materials either in or out of the bean. Once volatiles are transported to the surface of the bean, they are oxidized or evaporate, and you can never recover that loss. Eventually all desirable compounds are lost or transformed, leaving mainly the cellulose structure of the bean. Many call this "baggy" or "wet cardboard", which is essentially, all that's left.

We don't consider oldish flavors in a past crop coffee to be contamination or defect, but rather an expected and accepted part of coffee "fading" in un-protected jute. However, in a new crop coffee, we would never accept a coffee that exhibited signs of oldishness or "baggy" jute flavors.

As far as contamination is concerned, there are a lot of weird flavors that can end up in coffee. We recently cupped an incredibly floral central American coffee, and learned that somehow handsoap had been spilled on the bag prior to shipment and the artificial fragrance had leeched through the plastic sample bag and into the coffee. This fragrance survived the roast and ended up in the cup. Coffee is hygroscopic and will soak up almost anything placed next to it and store this contamination mainly in its fats. Some countries treat jute with a petroleum-based preservative which imparts a fumy, menthol and diesel flavor to the cup. Many times, the first indication of contamination can be detected from simply smelling the green beans prior to roasting.

We want to find ways to preserve coffee's nuance and delicate flavors. Coffee that's only 3 months off the tree should still taste fresh and vibrant, but many times this is not the case. Coffee is easily damaged by fluctuation in temperature and humidity, and can suffer considerable loss of quality during transport from origin to its destination alone. This is so common in the industry, that many cuppers (including myself at times) fail to recognize it in the cup. Most coffee shops would never accept stale pastries from their baker, yet they sell old coffee (green as well as roasted) all the time. The question that we're interested in exploring is how to minimize fading in green coffee in a realistic and sustainable way. What are the ideal storage conditions for green and how much fading naturally occurs under ideal storage conditions verses how much do we enforce and expedite because of careless practices and lack of good information?

barismo: Moisture appears the biggest problem in green, can you detail some byproducts of moisture problems?Jamin: Mold growth is probably the biggest problem. Mold growth can occur in green coffee when water activity in the bean is at favorable levels to support mold growth. Mold growth can lead to Orchratoxin contamination in green coffee. This is regulated quite heavily in Europe and other countries around the world (though not in the US), since Ochratoxin A is a mycotoxin that has been shown to cause renal toxicity and liver and kidney cancer. Most studies I've seen involving mold and roasted coffee, however, refer to the fate of Ochratoxin A during further processing (roasting, brewing, etc.).

Other problems include flavor taints, or loss of flavor, as described earlier. Mold is a terrible thing to taste in coffee.

barismo: We have focused a lot on defects (not taints) on the small scale and have actually noted increases in pales, molds, and other discolorations as coffees age, can you elaborate on this phenomena and what roasters can do to slow or stop this once coffees are to be warehoused?Jamin: Coffee that is improperly dried at origin can exhibit these characteristics. Also, coffee that is stored in high humidity can mold and change color. Certain coffees from Indonesia are shipped with very high initial moisture. These coffees are less stable and can break down, discolor, or mold more readily than properly dried coffee. They are also more susceptible to insect damage. Coffee that has been exposed to extremes in temperature and humidity, especially large fluctuations, can also exhibit these traits.

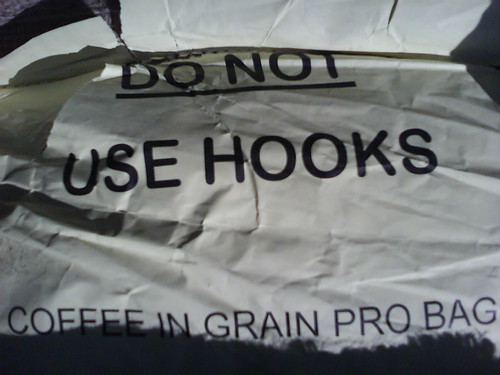

barismo: Can you detail the hermetic grain tent (GrainPro)at origin idea?Jamin: I can offer a brief explanation. Storing coffee at origin can be challenging because of infrastructure and lack of adequate storage conditions. GrainPro, Inc. is a company that manufactures products mainly for the seed industry and has a product for preserving food sources such as grain and seed in countries of origin, mainly in the third world. They've developed a tent or "cocoon" for controlling temperature and humidity for storage of bulk coffee at origin. Coffee in parchment is placed into shipping container-sized cocoons that are designed much like a Hazmat suit with special zippers and a layer of nearly-impermeable plastic. These can be set up outdoors with a refractive tarp for shade and seal hermetically to keep pests and other maladies at bay. An interesting side effect of hermetically sealing coffee, however, is that the natural respiration of the coffee actually flushes the chamber with CO2, creating an almost ideal environment for coffee storage while killing insects and molds. Studies have been undertaken that show almost no decrease in cup quality or moisture content of coffee stored this way for 9 months.

barismo: Freezing is a controversial topic. Can you detail current investigations into freezing, flash freezing, and related thawing issues?Jamin: Freezing is controversial, and I don't have enough direct experience to feel comfortable commenting on this.

barismo: What are the issues we face economically and customs related in supplanting jute as a packing material?Jamin: Jute has some great things going for it: It's cheap, and relative to other man-made products, especially petroleum based plastics, it is environmentally friendly. The drawback is that it provides almost no protection from environmental conditions that are detrimental to coffee quality. Coffee is largely a cost-driven economy, with few willing to compete on quality. Like anything, there must be a desire within the market for emerging storage technologies, and a willingness to embrace the pricing changes that this would certainly demand, before this will be explored seriously by those able to provide it.

Rice is about as commodity as it gets. Well, I like to think that but then I have been noticing that even with something like rice, care given to packaging is moving well ahead of what we deal with in green coffee.

Rice is about as commodity as it gets. Well, I like to think that but then I have been noticing that even with something like rice, care given to packaging is moving well ahead of what we deal with in green coffee.